Small production run

CNC metal milling services are also perfect for relatively smaller productions. In many cases, all that is needed is a CAD file which has additional extended production costs. The parts that are cut out from the original material should be ready for use. An appropriate CNC milling machine should be easy to operate.

Looking at the form

The entire process of CNC machining is also known to be precise. This implies that it offers exact repeatability. Typically, the machine tools are known to move seamlessly on the axes while creating a complex and three-dimensional shape, which should almost be impossible.

The quality of the machine makes it an appropriate tool for various manufacturing processes especially for jobs that need some admirable level of precision.

Final Thoughts -CNC Lathes

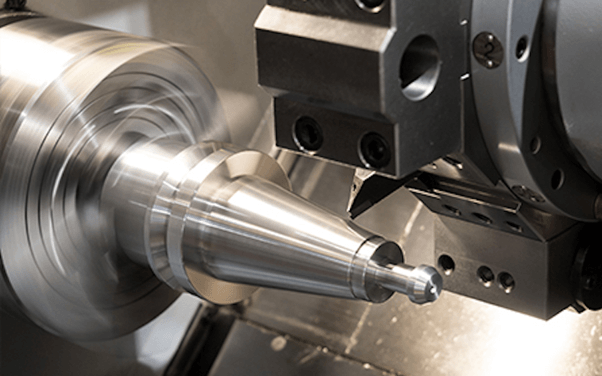

Typically, CNC lathes can be utilized in the case of metal machining. And when the CNC metal machining is appropriately done on the lathe, it can also be termed as turning. In many cases, the lathe operates on the same line as that CNC mill. And while the mill holds the block in a single place, the lathe will end up spinning the blank right on the RPM.

CNC Metal Prototyping

CNC metal processes can be utilized in the process of creating prototypes when it comes to making sure that prototypes are fit and functional. The process usually allows manufacturers to successfully test new parts while making the necessary changes before investing in mass production.

That said, CNC metal processing is affordable in many ways. It also allows consumers to have the chance to delve into the lump-sum production of various products. The prototyping bit allows manufacturers to make necessary changes before production. CNC machining is also known to be quicker and easy to control. In the long run, you will discover that you can easily get the revised part ready for initial testing.

Small production run

CNC metal milling services are also perfect for relatively smaller productions. In many cases, all that is needed is a CAD file which has additional extended production costs. The parts that are cut out from the original material should be ready for use. An appropriate CNC milling machine should be easy to operate.

Looking at the form

The entire process of CNC machining is also known to be precise. This implies that it offers exact repeatability. Typically, the machine tools are known to move seamlessly on the axes while creating a complex and three-dimensional shape, which should almost be impossible.

The quality of the machine makes it an appropriate tool for various manufacturing processes especially for jobs that need some admirable level of precision.

Final Thoughts -CNC Lathes

Typically, CNC lathes can be utilized in the case of metal machining. And when the CNC metal machining is appropriately done on the lathe, it can also be termed as turning. In many cases, the lathe operates on the same line as that CNC mill. And while the mill holds the block in a single place, the lathe will end up spinning the blank right on the RPM.

The meaning of metal machining has evolved over the past few years. Today, machining refers to a reliable manufacturing term that encompasses a range of different technologies as well as techniques. CNC Metal machining is the removal of material from a workpiece via a power-driven machine or tool to shape it into a specified design. Why invest in CNCmetal?

The metal machining process is highly reliable, and it entails the utilization of high speed in removing plastic from metal. Usually, the process is referred to as subtractive. This implies that the machine will remove some form of material from the blank space to reveal the hidden part.

Typically, the machine is capable of removing material from the blank to reveal the final part. And since the machine is controlled using computers, the whole process can be repeated, thereby resulting in the same identical part each time. In this way, manufacturers get to achieve large production or different product in a record timeline.

It is typical for metal parts to need some element of machining in the process of manufacturing. Materials like rubbers and plastic can also get fabricated via the machining processes.

Benefits of metal machining

CNC Metal Prototyping

CNC metal processes can be utilized in the process of creating prototypes when it comes to making sure that prototypes are fit and functional. The process usually allows manufacturers to successfully test new parts while making the necessary changes before investing in mass production.

That said, CNC metal processing is affordable in many ways. It also allows consumers to have the chance to delve into the lump-sum production of various products. The prototyping bit allows manufacturers to make necessary changes before production. CNC machining is also known to be quicker and easy to control. In the long run, you will discover that you can easily get the revised part ready for initial testing.

Small production run

CNC metal milling services are also perfect for relatively smaller productions. In many cases, all that is needed is a CAD file which has additional extended production costs. The parts that are cut out from the original material should be ready for use. An appropriate CNC milling machine should be easy to operate.

Looking at the form

The entire process of CNC machining is also known to be precise. This implies that it offers exact repeatability. Typically, the machine tools are known to move seamlessly on the axes while creating a complex and three-dimensional shape, which should almost be impossible.

The quality of the machine makes it an appropriate tool for various manufacturing processes especially for jobs that need some admirable level of precision.

Final Thoughts -CNC Lathes

Typically, CNC lathes can be utilized in the case of metal machining. And when the CNC metal machining is appropriately done on the lathe, it can also be termed as turning. In many cases, the lathe operates on the same line as that CNC mill. And while the mill holds the block in a single place, the lathe will end up spinning the blank right on the RPM.