• Inlet Section

The Inlet section is the end connection of fluid/gas which flows inside. This linear segment extends from the orifice meter.

• Outlet Section

Just like a linear inlet, it is also a linear section. It’s a point from where the pressure of fluid/gas discharged is found out.

Working Principle

The working of the orifice meter is based on the Differential Pressure Measurement principle, which states that the pressure drop along with the meter is proportionate to the square of the flow rate.

The liquid/gas flow rate is determined when it moves through the orifice plate.

This results in a pressure drop along with the place that fluctuates with the flow rate that causes the differential pressure between the inlet & outlet divisions.

The orifice meter calculates the flow rate by measuring this pressure drop.

Where To Use

While reading about the orifice meter, this question may come to your mind in which industries you can use this system. Here we have a few industrial utilization examples. You can use it.

- Petrochemical plants

- Oil Filtration Plants

- Water treatment plants

- Refineries

- Natural gas industries

Orifice Meter Types

There are four different types of orifice meters that include

- Eccentric orifice meter

- Conical orifice meter

- Segmental orifice meter

- Quadrant orifice meter

All these types differ based on their fluid accessibility properties.

Why Use This

The orifice meter is very popular among many industrial plants. The main reason for its popularity is the simple & cheap system. The meter will provide you with both vertical and horizontal flow based on your requirement. You need only a small area for the installation, which is actually quite an easy process. This meter offers a great range of flow rates, even in large pipes. All these reasons cause an increasing trend of these meters in various field areas.

Final Words!

An industrial setup is a much more complex process than your thinking. It needs a lot of time, effort, money, and machinery quality. Wan Hui is providing you with the best cost-effective solution that will provide you with quality and ease of use. Explore different options on the company website.

• Orifice Plate

It is used to produce a pressure drop that assists the flow rate measurement. It’s present between the inlet & outlet division of the orifice.

• Inlet Section

The Inlet section is the end connection of fluid/gas which flows inside. This linear segment extends from the orifice meter.

• Outlet Section

Just like a linear inlet, it is also a linear section. It’s a point from where the pressure of fluid/gas discharged is found out.

Working Principle

The working of the orifice meter is based on the Differential Pressure Measurement principle, which states that the pressure drop along with the meter is proportionate to the square of the flow rate.

The liquid/gas flow rate is determined when it moves through the orifice plate.

This results in a pressure drop along with the place that fluctuates with the flow rate that causes the differential pressure between the inlet & outlet divisions.

The orifice meter calculates the flow rate by measuring this pressure drop.

Where To Use

While reading about the orifice meter, this question may come to your mind in which industries you can use this system. Here we have a few industrial utilization examples. You can use it.

- Petrochemical plants

- Oil Filtration Plants

- Water treatment plants

- Refineries

- Natural gas industries

Orifice Meter Types

There are four different types of orifice meters that include

- Eccentric orifice meter

- Conical orifice meter

- Segmental orifice meter

- Quadrant orifice meter

All these types differ based on their fluid accessibility properties.

Why Use This

The orifice meter is very popular among many industrial plants. The main reason for its popularity is the simple & cheap system. The meter will provide you with both vertical and horizontal flow based on your requirement. You need only a small area for the installation, which is actually quite an easy process. This meter offers a great range of flow rates, even in large pipes. All these reasons cause an increasing trend of these meters in various field areas.

Final Words!

An industrial setup is a much more complex process than your thinking. It needs a lot of time, effort, money, and machinery quality. Wan Hui is providing you with the best cost-effective solution that will provide you with quality and ease of use. Explore different options on the company website.

• Flow Conditioner

A flow conditioner boosts the linear liquid/gas flow in the meter tube’s inlet section. It is installed in the inlet division.

• Orifice Plate

It is used to produce a pressure drop that assists the flow rate measurement. It’s present between the inlet & outlet division of the orifice.

• Inlet Section

The Inlet section is the end connection of fluid/gas which flows inside. This linear segment extends from the orifice meter.

• Outlet Section

Just like a linear inlet, it is also a linear section. It’s a point from where the pressure of fluid/gas discharged is found out.

Working Principle

The working of the orifice meter is based on the Differential Pressure Measurement principle, which states that the pressure drop along with the meter is proportionate to the square of the flow rate.

The liquid/gas flow rate is determined when it moves through the orifice plate.

This results in a pressure drop along with the place that fluctuates with the flow rate that causes the differential pressure between the inlet & outlet divisions.

The orifice meter calculates the flow rate by measuring this pressure drop.

Where To Use

While reading about the orifice meter, this question may come to your mind in which industries you can use this system. Here we have a few industrial utilization examples. You can use it.

- Petrochemical plants

- Oil Filtration Plants

- Water treatment plants

- Refineries

- Natural gas industries

Orifice Meter Types

There are four different types of orifice meters that include

- Eccentric orifice meter

- Conical orifice meter

- Segmental orifice meter

- Quadrant orifice meter

All these types differ based on their fluid accessibility properties.

Why Use This

The orifice meter is very popular among many industrial plants. The main reason for its popularity is the simple & cheap system. The meter will provide you with both vertical and horizontal flow based on your requirement. You need only a small area for the installation, which is actually quite an easy process. This meter offers a great range of flow rates, even in large pipes. All these reasons cause an increasing trend of these meters in various field areas.

Final Words!

An industrial setup is a much more complex process than your thinking. It needs a lot of time, effort, money, and machinery quality. Wan Hui is providing you with the best cost-effective solution that will provide you with quality and ease of use. Explore different options on the company website.

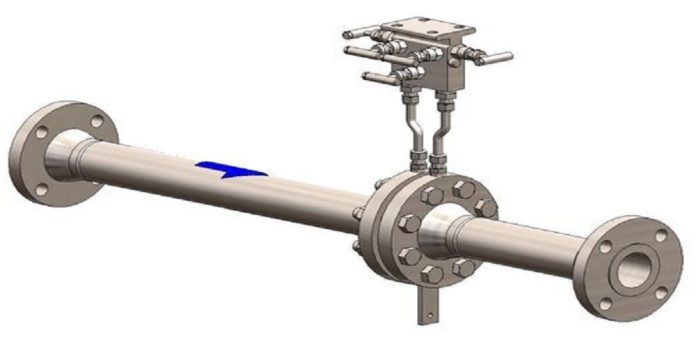

Measure the flow rate of fluid or gas with an orifice meter, an instrument consisting of three main components; orifice plate, plate housing, & meter tube.

You need to approach this meter to construct any liquid flow system, especially when working on large projects. It’s a kind of restriction or conduit that crafts a pressure drop in the system.

While looking for an Orifice Flow Meter for your industrial setups, you might find many options in the market, from local to branded ones. However, Wan Hui Machinery Co., Ltd will provide you with all the required options reasonably priced and quality assurance.

Before jumping into the orifice collection, let’s briefly overview its working, construction, and applications.

Orifice Meter Construction

• Flow Conditioner

A flow conditioner boosts the linear liquid/gas flow in the meter tube’s inlet section. It is installed in the inlet division.

• Orifice Plate

It is used to produce a pressure drop that assists the flow rate measurement. It’s present between the inlet & outlet division of the orifice.

• Inlet Section

The Inlet section is the end connection of fluid/gas which flows inside. This linear segment extends from the orifice meter.

• Outlet Section

Just like a linear inlet, it is also a linear section. It’s a point from where the pressure of fluid/gas discharged is found out.

Working Principle

The working of the orifice meter is based on the Differential Pressure Measurement principle, which states that the pressure drop along with the meter is proportionate to the square of the flow rate.

The liquid/gas flow rate is determined when it moves through the orifice plate.

This results in a pressure drop along with the place that fluctuates with the flow rate that causes the differential pressure between the inlet & outlet divisions.

The orifice meter calculates the flow rate by measuring this pressure drop.

Where To Use

While reading about the orifice meter, this question may come to your mind in which industries you can use this system. Here we have a few industrial utilization examples. You can use it.

- Petrochemical plants

- Oil Filtration Plants

- Water treatment plants

- Refineries

- Natural gas industries

Orifice Meter Types

There are four different types of orifice meters that include

- Eccentric orifice meter

- Conical orifice meter

- Segmental orifice meter

- Quadrant orifice meter

All these types differ based on their fluid accessibility properties.

Why Use This

The orifice meter is very popular among many industrial plants. The main reason for its popularity is the simple & cheap system. The meter will provide you with both vertical and horizontal flow based on your requirement. You need only a small area for the installation, which is actually quite an easy process. This meter offers a great range of flow rates, even in large pipes. All these reasons cause an increasing trend of these meters in various field areas.

Final Words!

An industrial setup is a much more complex process than your thinking. It needs a lot of time, effort, money, and machinery quality. Wan Hui is providing you with the best cost-effective solution that will provide you with quality and ease of use. Explore different options on the company website.